Global trade is such an integral part of our everyday lives that you might not have thought about all the effort that goes into it. But shipping items between destinations in so many parts of the world in such enormous volumes is a massive undertaking.

Cartons and pallets are transported by road, rail and air. The objective, of course, is to ensure they get to their end destination in good condition without being damaged or getting lost along the way. But these units need to be correctly labelled to get to where they need to go.

This is where the Serial Shipping Container Code (or SSCC) comes in. Serial Shipping Container Codes provide an international standard with identification numbers to track individual shipping units at each step of their journey.

In this guide, we’ll take a closer look at SSCC labelling, what it does, and why it matters.

- What is an SSCC Label?

- Key Components of SSCC Labels

- SSCC Label Positioning and Placement

- Why do we use SSCC Labels? The Benefits of SSCC Labelling

- The Challenges of SSCC Labelling

- SSCC Labelling Solutions

- The Future of SSCC Labelling

- Summary

- SSCC Labelling FAQs

A PDF version of this guide is also available to download at the bottom of the page.

What is an SSCC Label?

The Serial Shipping Container Code, or SSCC, is an 18-digit number that identifies shipping units, including pallets, cartons and containers. Logistic units are assigned a unique SSCC, which can be used to identify that particular unit at any stage of the supply chain so that they are traceable from end to end.

As well as being used for tracking purposes, the SSCC also contains details of the contents of each load. SSCC numbers are printed in digits and in the form of GS1-128 barcodes on GS1 shipping labels. This same information must also be included in electronic data interchange (EDI) messages relating to the unit as it is in transit.

Because each unit is assigned a unique SSCC, this ensures that there are no duplicate codes, preventing misidentification.

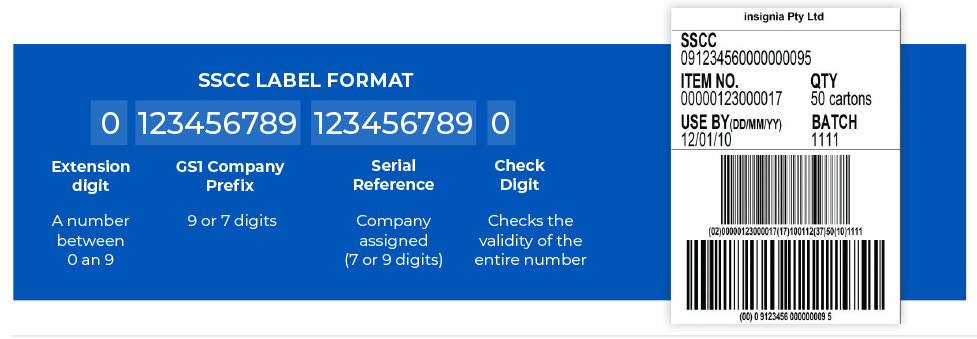

Key Components of SSCC Labels

SSCC labels must include several key components to identify and track units at every stage of their journey along the supply chain.

An SSCC label is comprised of the following:

- A GS1 Company Prefix, a unique number issued to companies when they join GS1 and which is used to identify them as the owner of a particular product.

- A unique, sequentially assigned serial reference number, used to identify individual logistics units.

- An application identifier; a numeric prefix used to indicate the data format and structure within the barcode.

- A check digit, used for error detection within the SSCC number to ensure the accuracy of the data included in the barcode.

- A GS1-128 barcode representing the SSCC number, including the GS1 Company Prefix, serial reference, application identifier and check digit in a machine-readable format.

- SSCC labels also include the SSCC number in the form of printed digits so that it can be manually read without the need for a barcode scanner.

In terms of layout, the GS1 logistics label is divided into three sections:

- Top section: includes company name, logo and any additional information.

- Middle section: includes the unit’s SSCC and any further information (e.g. batch number and use-by dates) according to the AI standards, printed in a form humans can read.

- Lower section: GS1-128 barcodes with the encoded data displayed beneath each barcode. There is no limit to the number of GS1-128 barcodes on a GS1 label, but the SSCC should always be included in the lowest barcode printed on the label.

SSCC Label Positioning and Placement

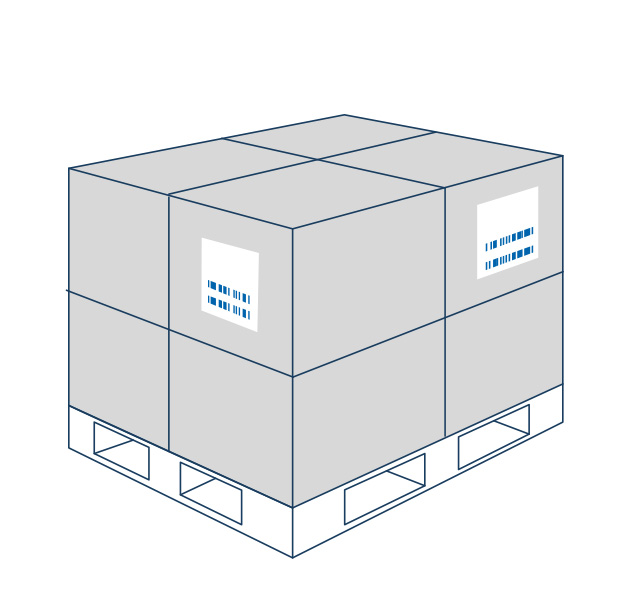

SSCC logistics labels can be used on any shipping unit but are typically applied to pallets. According to GS1, two identical labels should be attached to adjacent sides of the unit, one on the short side and another on the long right-hand side.

For units over 1,000mm in height, labels should be placed so that the barcodes are printed no more than 800mm and no less than 400m above the floor. For units below 1,000mm, labels should be placed as high as possible but the barcodes must be no more than 800mm and no less than 32mm from the unit’s base. The barcode’s edge should be no closer than 50mm to a vertical edge of the unit.

While GS1’s General Specifications do not stipulate a standard size, A5 labels (148mm x 210mm) are generally used so that there is sufficient space for additional information. GS1 guidelines state that label material and printer ink must be compatible, and material or ink which is heat-sensitive (such as inks that are easily smudged) is not acceptable. Barcodes should be printed in black on a white background.

Why do we use SSCC Labels? The Benefits of SSCC Labelling

There are many benefits to the SSCC labelling system. SSCC labels greatly enhance traceability and allow for seamless tracking of each logistic unit at every stage of its route, from initial dispatch to arrival at its intended end destination.

This, in turn, facilitates enhanced inventory management and improves business communication. It streamlines the logistics and shipping processes, ensuring greater efficiency while reducing errors – which reduces the need for manual intervention.

SSCC labelling also ensures compliance with GS1 standards. Because SSCC numbers can be read and processed by machines, this improves data reliability, reduces human error and lowers costs.

Ultimately, SSCC labelling also improves customer satisfaction by ensuring that delivery dates are more reliable – so people have a clearer idea of when items will arrive – and that the whole process of making and receiving orders runs more efficiently.

The Challenges of SSCC Labelling

Errors in SSCC labelling can cause delays to shipments or even mean that goods are rejected at their destination. One of the most common causes for failure is that SSCC labels include the wrong or different information on each label. Compliant SSCC labelling requires a minimum of two identical labels – so if they’re different, you have a big problem.

Taking that a step further, SSCC Label information must also match what’s stored in your software/database as it’s sent to the recipient. And these two facets of SSCC labelling are where companies can tie themselves in knots.

The SSCC labelling process is arguably relatively easy. Still, factor in multiple versions and the need to integrate with software systems, and it’s no longer a case of firing up a printer and sticking on a label.

SSCC Printing Issues

When it comes to printing and application, a common problem is print quality; many SSCC labels are printed to an inadequate standard – i.e with smudged or illegible barcodes. This can result in barcodes that can’t be read by scanners – which can cause serious problems at distribution centres. Pallets may be rejected as a result of this.

Printing and setup errors may also result in information missing from barcodes, meaning scanners cannot read them. This, in turn, can cause delays with knock-on effects throughout a supply chain.

SSCC Positioning Issues

Incorrect SSCC label positioning can cause scanning problems as scanners may be unable to read the information contained in the barcodes. Using the wrong label adhesive or incompatible packaging can also cause labels to not stick properly to the surface of the unit, which can mean that they come off during transit.

This may make sending them on to their next destination impossible, meaning that they get lost along the way.

In the next section of this guide, we’ll explore some of the solutions Cobalt provides to help prevent these situations from occurring.

SSCC Labelling Solutions: Never Ship out a Bad Label

Cobalt’s commitment to quality in meeting GS1 standards for SSCC labelling solutions makes us the supplier of choice for both automated print and apply applications for pallets and manual application too.

We have a range of options to help companies get to grips with SSCC labelling and experience in many sectors, particularly in FMCG and food and beverage industries where supplying into UK supermarket chains means compliant and efficient SSCC labelling isn’t a nice-to-have, but an essential.

While the core focus of any SSCC labelling solution is naturally the setup, printing and application of a correct label, at Cobalt, we take things a step further with two specific SSCC labelling solutions: Smart SSCC and Cobalt Pallet Manager – talk to our team for more information about these solutions.

Smart SSCC is our proprietary solution that enables our customers to build out compliant SSCC labels in real-time at the start of the process, using data collected as pallets are prepared.

Available as a manual solution, semi-automated or fully automated, Smart SSCC can generate labels for complete, part or mixed pallets in real-time, offering massive savings in terms of time and set up headache.

Whilst at the end of the process, Cobalt Pallet Manager is our enhanced validation and security product that scans both labels and performs several safeguard checks for SSCC labels prior to shipping:

- Verifies the integrity of the print quality in terms of machine readability

- Checks the labels match up front and side (and other faces if necessary)

- Checks the data on each label matches the contents of the consignment

- Checks the data matches the information held in your software/systems

Any failure at this stage will result in visible and/or audible warnings, so you’ll never ship out a bad SSCC label.

In terms of SSCC labelling production, we offer a range of standalone printers and automatic print and apply machines to handle this.

For scenarios where production throughput is relatively static and slow-speed and the same products or range of products are prepared for shipping day in, day out, an industrial printer capable of printing 6” labels might be sufficient.

These can be configured to work with your existing labelling software, or we recommend Loftware NiceLabel. For ease of use for the operator, industrial printers can be set up in a ‘peel and present’ configuration, whereby the printer peels the label away from the backing sheet so there’s minimal manual handling.

For higher throughput environments, our specific pallet labelling machines, designed with SSCC in mind, offer 2-sided and 3-sided automatic labelling. Capable of running at speeds of up to 120 pallets per hour when applying to two sides of a pallet or 80 per hour when applying to three sides of a pallet, speed, accuracy and efficiency are guaranteed.

The inclusion of our Smart SSCC product makes the management of many to one pallets (i.e. a mix of finished products loaded onto the same pallet), a simple process.

Again, this can be configured for environments where labels are manually applied or can be highly automated using a range of scanning, data collation, label management and print and apply technologies.

The short answer is: SSCC labelling is complicated, but we have plenty of experience in making this simple. We can get you up and running quickly – ideal when customer demands or requirements for SSCC labels change – such as supermarkets.

The Future of SSCC Labelling

There are some key medium to long-term trends to be aware of with regard to SSCC labelling. For example, the traditional barcode component may be phased out over the coming years as the QR code, which can encode up to 100 times more information, replaces it.

Ongoing trends which we can expect to continue in the years ahead include the increased use of data visibility and analytics, leveraging data to enhance decision-making and optimisation of logistics processes, and the increased use of more sustainably sourced materials for SSCC labelling to reduce its environmental impact.

The integration of advanced technologies such as artificial intelligence and machine learning is also likely to have a significant bearing on supply chains and in turn, on SSCC labelling. The increased focus on cybersecurity, too, may influence the future shape of the SSCC system.

While the future is never clear, choosing an SSCC labelling partner that keeps their finger on the pulse is vital, and at Cobalt we’re keen to ensure our machinery and solutions are as futureproof as possible.

Summary

SSCC labelling has come to play a central role in logistics operations. Its benefits are manifold: it has helped reduce errors, enhance supply chain visibility and reliability, ensure compliance with industry standards and facilitate the efficient movement of vast quantities of goods worldwide.

As international commerce continues to grow, the retail and logistics industries will be faced with handling even larger volumes of international shipments. Implementing SSCC numbers is likely to play a central role, imposing a coherent global standard so that companies can ensure effective identification and communication at each stage of the supply chain.

Businesses that have not already embraced SSCC labelling could, therefore, risk finding themselves at a disadvantage compared to their rivals.

Cobalt’s unrivalled expertise in print and apply labelling solutions means we offer a wealth of SSCC labelling options, with modular solutions designed for your specific needs. Contact us today to find out more.

SSCC Labelling FAQs

Can SSCC labels be reused?

No, an SSCC label must be unique to an individual shipping container. Reusing an SSCC would lead to confusion and errors in tracking and logistics, potentially resulting in lost shipments.

What is the difference between UCC and SSCC?

“SSCC” refers to a specific code used to identify shipping containers within the supply chain. The UCC (Uniform Code Council) is the organisation that originally developed the SSCC standard and other barcoding standards.

How do I find an SSCC code?

SSCCs are created individually per shipment and each one contains a unique identifying code, specific to your company. To obtain an SSCC code, you must first receive a code for your company from your local GS1 member organisation. Once you have a company code, you can generate SSCCs for your shipments.

How is an SSCC check digit calculated?

The check digit for an SSCC code is calculated using a mathematical formula (the Modulus 10, Weight 3 calculation) applied to the other digits in the code. This ensures data accuracy and helps prevent errors in scanning and processing.

What is the difference between an SSCC-18 and SCC-14 barcode?

The number refers to the number of digits in the code – an SSCC-18 code features 18 digits, while an SCC-14 code has 14 digits.

SSCC-18 and SCC-14 serve two different functions. SCC-14 codes (now referred to as GTIN-14 codes) are used to identity a specific product and package quantity, but not purchasing or order information. SCC-14 codes can be applied at the point of manufacturing and are applied to all items that match this product and package quantity, regardless of their shipping information or destination.

SSCC-18 codes are unique to each shipment and can be used alongside an SCC-14/GTIN-14 code to add identifying information about the items in the shipment. 18 digits are beneficial as they allow for granular tracking and broad integration with international systems.

What does GTIN mean?

GTIN stands for Global Trade Item Number. It is a unique identifier for accurately tracking products, items, and services throughout supply chains.

What is the SSCC on a shipping label?

The SSCC on a shipping label is the Serial Shipping Container Code—a unique identifier for the shipping container. It allows for efficient tracking and tracing of the container as it moves through the supply chain.

What size is an SSCC label?

The Standard size of an SSCC label is 148x210mm (A5) on two adjacent sides of a shipping container/pallet.

However, the size of an SSCC label can vary – as long as it adheres to GS1 standards. The label’s dimensions should be large enough to accommodate both the barcode and human-readable information and allow for compliance with any relevant industry-specific requirements.

What is the difference between GTIN and SSCC?

GTIN and SSCC are both identifying codes that exist as part of the GS1 system. A GTIN identifies individual products and can be used with various product types in many shipping and logistics applications. An SSCC is only used as a unique identifier for shipping.