Cobalt Green

Cobalt Green is our commitment to doing what we can to drive sustainability improvements in our industry.

Cobalt Green is our commitment to doing what we can to drive sustainability improvements in our industry.

As of June 2022, we have achieved full carbon neutrality across the business, from our day-to-day operations to our delivery processes and event attendance. Cobalt Systems is contributing to a number of CO2 reduction projects around the world; we are also in the process of electrifying our commercial fleet and are actively developing a number of all-electric solutions to help our customers reduce waste.

This drive for improvement is in the wider context of the manufacturing industry as a whole and we’re very proud to be contributing to a more sustainable UK supply chain.

Learn More

Our Founder and Managing Director Tony Hunt discusses sustainability in an interview with PPMA TV at PPMA 2023.

The NEXUS 20 E-Blade labels a fixed point on cases of variable height. For products of a fixed width, the NEXUS 20 E-Blade offers an ideal solution for green and efficient labelling on one side of a box or case.

The NEXUS E-Contact runs independent “print” and “apply” stages, synchronising the processes when needed to provide maximal speed and efficiency. It can apply labels to the side, top, bottom, or front of packs, storing excess labels if necessary to deal with peaks in production.

The NEXUS 20 E-Beak provides real-time front-of-pack labelling at high speeds, without the need for compressed air. With no speed synchronisation or special conveyor systems required for operation, the Nexus 20 E-Beak is an industry-leading option for implementation and ownership costs.

Cobalt Systems recently installed a Print & Apply labelling automation solution into the North West food processing plant for a multi-national food producer as part of a green scheme to remove plastic packaging and improve environmental factors.

The end-of-line project, which formed part of the packaging area, was part of an upgrade on previously installed hardware. As part of the green scheme, the food producer developed cardboard cartons that can support the weight of heavier goods such as tins and cans. This packaging development reduces shrink wrap but retains the stability of the cans.

Read the Case Study

What opportunities exist for label application technology to drive sustainability?

As part of a longstanding desire to improve CSR, We are delighted to announce we are a certified carbon neutral organisation as of June 2022.

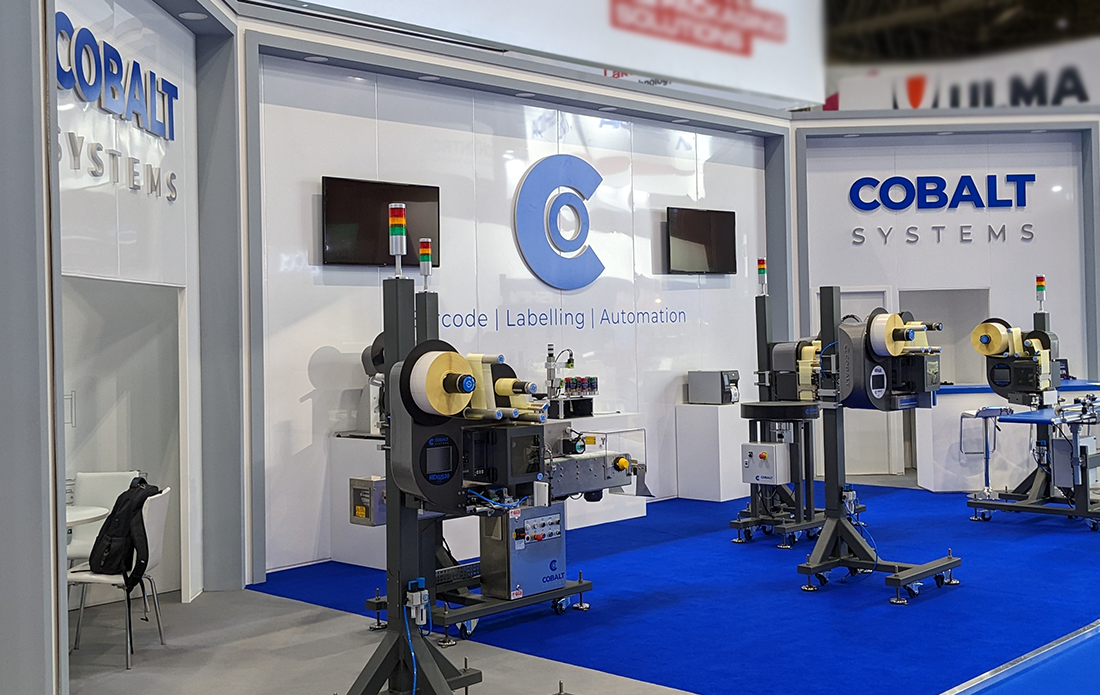

Cobalt Systems celebrates its 25th anniversary and reveals its next-generation print and apply labelling technology at PPMA TOTAL 2022.

"*" indicates required fields

Cobalt Systems Ltd,

Spitfire Road,

Cheshire Green Industrial Park,

Wardle,

Cheshire,

CW5 6HT

Fill out the form to subscribe to our newsletter.

"*" indicates required fields