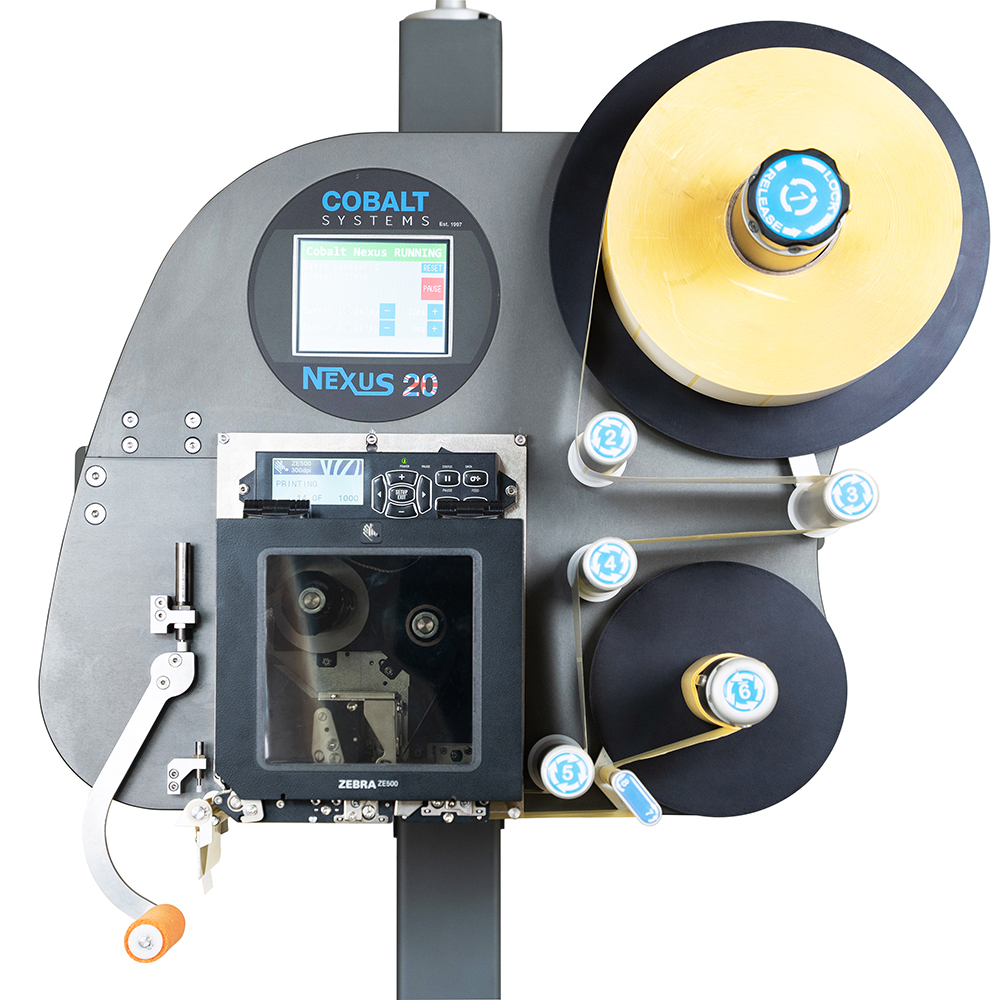

NEXUS 20 E-Beak

All-Electric Shrink Wrap Pack Printer Applicator

The NEXUS 20 E-Beak provides real-time front-of-pack labelling at high speeds, without the need for compressed air. With no speed synchronisation or special conveyor systems required for operation, the Nexus 20 E-Beak is an industry-leading option for implementation and ownership costs.

Providing print-and-apply labelling at speeds of over 80 packs per minute and with less waste than other options, the Nexus 20 E-Beak is ideal for low-maintenance, high-speed labelling of shrink-wrapped packs and canned products.

Use Cases

- Canned Products

- Variable Line Speed