Zebra Print Engines

In high-speed, high-throughput label printing environments, production, uptime and hardware availability are everything, and a reliable print engine is key to achieving this.

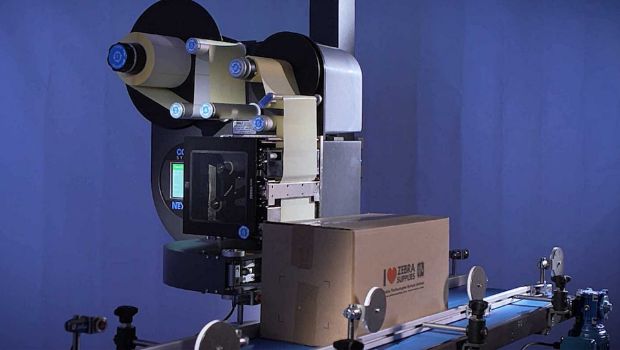

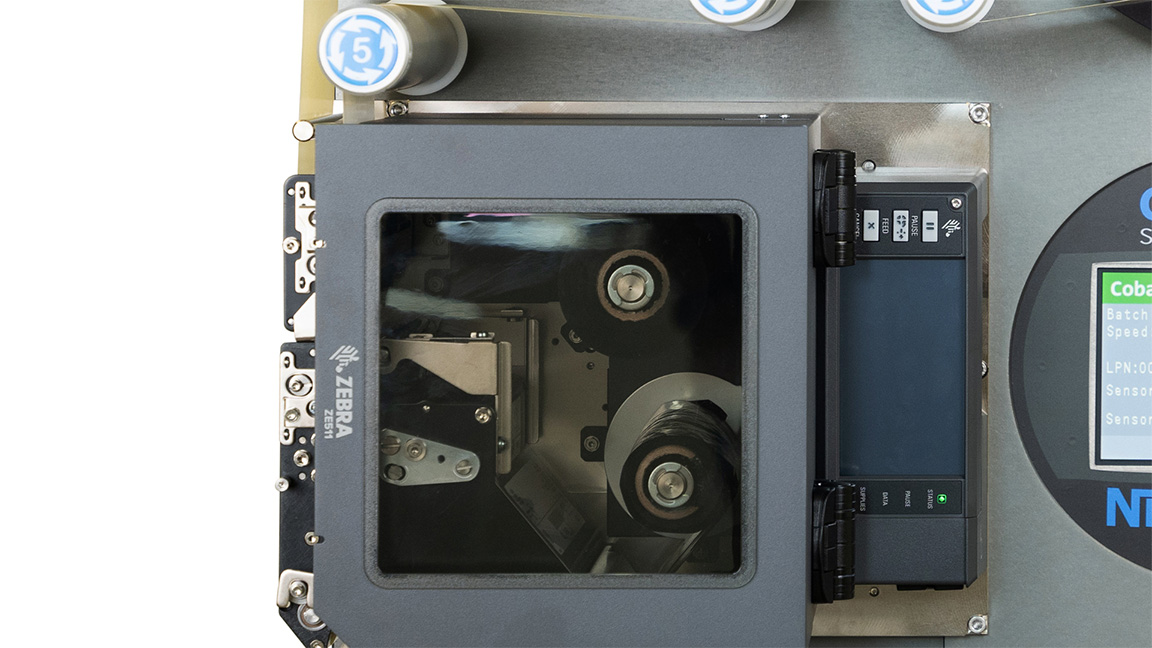

In all printer applicators on the market, the print mechanism, control and processing elements carry the biggest load, which means they are the most common cause of downtime. With our systems, all these elements are housed in one hot-swappable print engine box, so unlike other systems, if there is an issue, a replacement can be fitted in a matter of minutes. This allows any maintenance or repair to occur offline, whilst your line keeps running.

We only partner with the very best manufacturers of thermal transfer print technology; Zebra Technologies empowers those on the front line in retail, healthcare, transportation and logistics, manufacturing and other industries to achieve a performance edge – an edge that translates to delighted customers, better patient outcomes and superior business results. That’s why incorporating Zebra print engine technology into our print and apply solutions ensures the best results for our customers.