The rapid expansion of online commerce and the changing expectations of consumers – which have only grown more demanding in recent years – have put logistics, warehousing and manufacturing supply chains under ever-growing pressure.

This increased demand adds to the challenge of ensuring that orders are dispatched quickly and accurately – so that they get to where they need to be in good time. Technological solutions are helping the industry rise to this challenge.

In particular, there has been a trend towards the adoption of fixed scanners. In this guide, we’ll explain the advantages and applications of fixed industrial scanners, as well as looking at Zebra’s range of fixed scanners and what they can offer your business.

- What are fixed industrial scanners?

- Applications and benefits of fixed industrial scanners

- Fixed scanning options for business

A PDF version of our fixed scanner buyers’ guide is also available to download at the bottom of the page.

What are fixed industrial scanners?

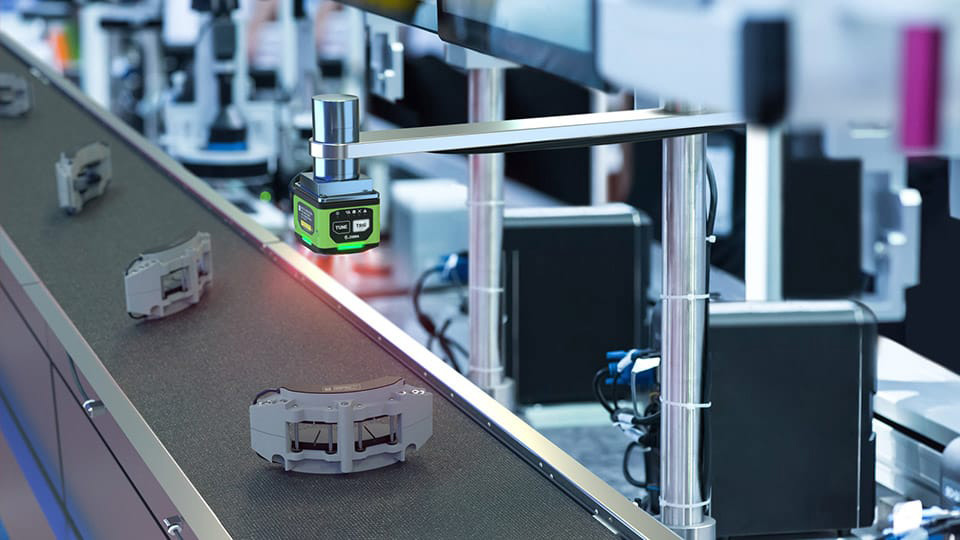

Fixed industrial scanners are devices used for automatic identification and data capture. They are usually installed at fixed points along a production line or other industrial facility, performing tasks including barcode scanning and image capture.

While fixed scanners and handheld scanners perform a lot of the same functions regarding data capture, there are important differences between the two. Most obviously, fixed scanners are – as the name implies – installed at fixed points within an industrial facility, including on conveyor belts and assembly lines, whereas handheld scanners can be portable.

Handheld scanners thus offer flexibility and mobility, but they may not be as quick as fixed scanners when it comes to capturing data. Fixed scanners are designed for high-speed operation, which is why they are particularly well suited to use in high-throughput facilities such as warehouses.

Applications and benefits of fixed industrial scanners

Fixed scanners can handle a variety of tasks and offer a wide range of benefits, and have applications in:

-

- Barcode scanning: Fixed scanners are commonly used to scan barcodes on pallets, packages and other goods. This provides a real-time overview of stock levels and inventory movements, which helps to ensure orders are fulfilled accurately.

- Label inspection: Warehouses, factories and other industrial environments use fixed scanners to inspect labels and ensure their quality, accuracy and placement on packages and containers.

- Quality control: Fixed scanners are used to scan barcodes to check batch numbers, product codes, expiration dates and other relevant information in order to ensure compliance with quality standards.

- Inventory management: Fixed scanners play a particularly important role in inventory management, which is a crucial consideration for warehouses. Items are scanned as they enter or exit, which enables accurate inventory management, stock replenishment and cycle counting. Inventory records are automatically updated as goods pass in and out of the warehouse.

- Data capture and reporting: Fixed scanners capture data and then pass it on to enterprise resource planning (ERP) or warehouse management software systems. Operational teams can therefore keep track of warehouse performance in real time, tracking KPIs and making more informed decisions based on the latest information.

The main benefits of fixed industrial scanners include:

- High-speed scanning: Fixed scanners are optimised for speed, which enables rapid identification, verification and sorting of items. This makes fixed scanners especially useful in warehouses and other such environments where there is a high quantity of items being processed at any one time.

- Enhanced accuracy: Because fixed scanners use cutting-edge technologies, they ensure that identification and quality control is consistently reliable and accurate. This is vital for tasks such as quality control, inventory management and traceability.

- Data-driven insights: Fixed scanners are capable of collecting large amounts of data during the scanning process. This data can then be analysed to gain insights into product quality, inventory levels and other processes. Equipped with this data, it’s possible to make informed decisions and optimise operations, improving productivity and standards.

- Better productivity and efficiency: Fixed scanners can enable businesses to free up manual labour. Because human employees no longer need to spend time on relatively menial tasks, they can be deployed elsewhere instead. This enables firms to streamline their operations and make more efficient use of human labour while enhancing productivity.

- Time saving: Fixed scanners can scan in any orientation and, because the operator doesn’t have to pick up a hand scanner every time, they help save time as well.

- Deployment: Fixed scanners can replace hand scanners with a USB cable. Therefore, actually deploying them and using them doesn’t require new infrastructure such as cabling and network structures. Essentially, you can just swap them out – which again spares you unnecessary time, inconvenience and effort.

Fixed scanning options for business

Zebra’s range of fixed industrial scanners is designed to help you meet the changing needs of your business, incorporating advanced technologies including machine vision.

Here’s what Zebra’s fixed scanners have to offer:

- FS10 Fixed Industrial Scanner: Easy to set up, deploy and run, Zebra’s FS10 fixed scanner is compact and easy to fit wherever you need it to go.

- FS20 Fixed Industrial Scanner: For high-quality scanning and real-time track-and-trace on every item, the FS20 is a practical and user-friendly choice. Again easy to set up and deploy, the FS20 offers multiple connectivity options for simple integration into your PLC or Host network.

- FS40 Fixed Industrial Scanner: Offering a comprehensive range of features for sophisticated track-and-trace, Zebra’s FS40 scanner is designed to meet the demanding requirements of today’s e-commerce market. It comes equipped with ImagePerfect+ technology, allowing it to process up to 16 images simultaneously for high read rates. It also has integrated lighting, so it can read barcodes consistently in varying light conditions and on surfaces that are prone to glare.

- FS70 Fixed Industrial Scanner: Also equipped with ImagePerfect+ technology, the FS70 fixed scanner from Zebra is configurable and customisable – so it can track and trace every item as it passes from production to storage to fulfilment. Compatible with almost any external lighting solution, the FS70 can read even the most challenging barcodes.

Fixed scanners play a central role in ensuring that items reach their intended recipients in a timely manner, and in excellent condition. The new generation of fixed scanners, equipped with a raft of new innovations and capabilities, is therefore proving crucial in helping businesses to keep up with the rapid pace of ecommerce and keeping customers satisfied.

Choosing the right fixed scanner for your business requires careful consideration. Cobalt supplies the full range of cutting-edge fixed industrial scanners from Zebra, and we’re always happy to work with you to help you find the perfect solution for your needs and budget.

For more than 25 years, Cobalt has been driving up standards in barcoding solutions and print-and-apply labelling. We deliver end-to-end barcoding solutions and first-class customer service. Get in touch with us today to discuss our wide range of Zebra barcoding systems.