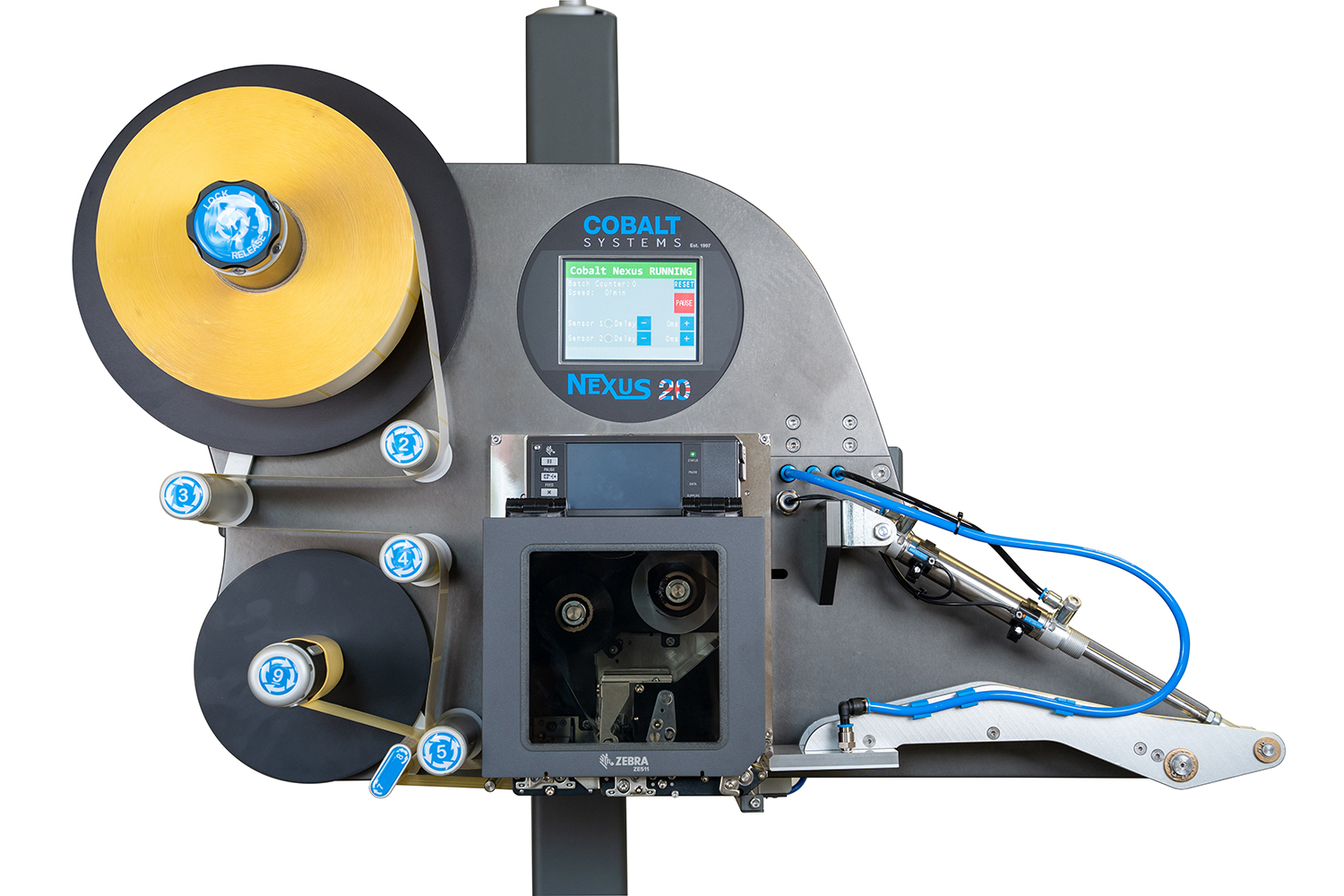

NEXUS 20 Pivot Long Reach

Long-Reach Label Application

Delivering labelling of 37 packs per minute, the Nexus 20 Pivot offers real-time labelling on the long side of shrink-wrapped packs, without having to turn the pack.

The Nexus 20 Pivot Long-Reach provides a simple solution to labelling cases of different heights on the same production line. It always applies labels to the front of cases, regardless of case height.

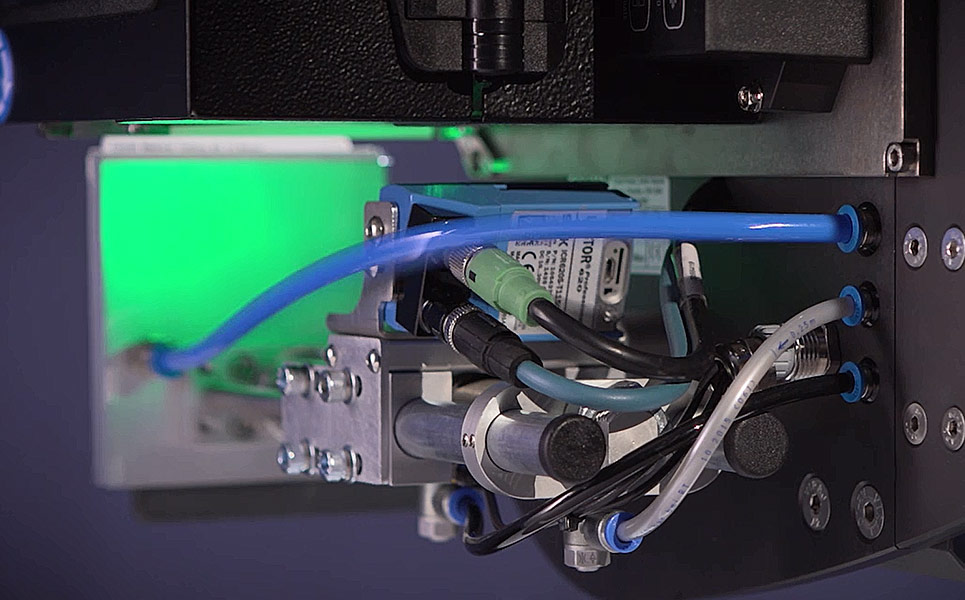

The Nexus 20 Pivot is available equipped with Cobalt Sentinel (model dependent) for on-board barcode verification and validation, or in a linerless configuration, for enhanced sustainability. It can be used as part of a wider system or as a standalone solution, with easy controls for operators.

This solution is also available in a high-speed, short-reach version.

Use cases

- Shrink Wrap Packs

- Variable Height Cases