Chatwins Bakery is a family-owned bakery with 20 shops and coffee lounges, employing more than 300 people across Cheshire, Staffordshire and North Wales. Founded in 1913 the business still embodies long held values of quality, value and excellence in customer service which is coupled to cakes, breads and other baked goods that are made with passion and care.

Historically, the company had hand-labelled all items to be sold, but the manual practice was restricting both operational throughput and the opportunity for growth. Hand labelling was also prone to human error and as such was compromising the quality of labelling.

As part of an investigation to improve labelling processes, Chatwins investigated setting up label templates for all their products, however, with hundreds of SKU’s, this was deemed impractical as it would quickly become expensive, inefficient and logistically challenging.

With ambitious goals of increasing logistical efficiency, improving label quality and reducing manual intervention, automation was the obvious path with a robust and flexible print and apply labelling solution.

Chris Hunt, Sales Director at Cobalt Systems, takes up the story: “Chatwins came to us with a barcode labelling problem and were looking for a trusted partner rather than just an equipment supplier. We had been recommended as print and apply solution specialists due to our strategic approach so it was a very good fit for our two businesses.”

Print and apply label expertise resolves multiple SKU challenge

Having recently undertaken a new branding exercise, it was essential for Chatwins that the labelling was both high quality and accounted for multiple variants across hundreds of SKU’s.

Cobalt designed a single label template in line with their new branding, which could utilise Chatwin’s database to automatically enable all specific data to reside on each label. This flexible approach alone saved the bakery an enormous amount of time and resource and dramatically reduced complexity.

Compact but efficient print and apply solution

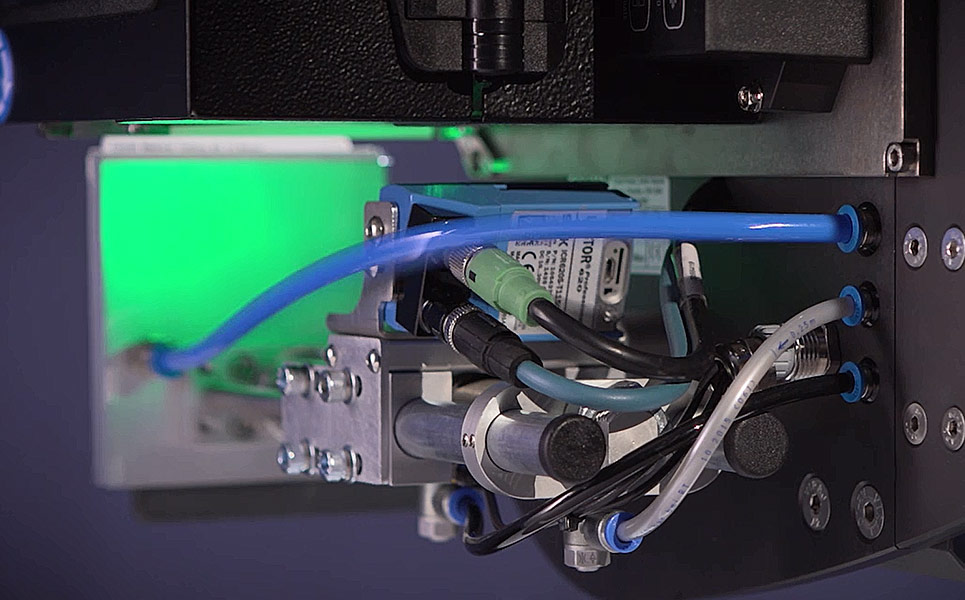

Another major challenge to the project was the space allowed for installation. To combat this, Cobalt specified a GS1 compliant, modular high-speed NEXUS Printer Applicator with an integrated conveyor and touch panel HMI.

Partner approach delivers powerful results

“From start to finish we have been well supported and guided. Cobalt engineers have been like an extension to our team, which has been invaluable, enabling an all-encompassing solution that has paid dividends for the business.” said Edward Chatwin, Managing Director of Chatwins.

As a result of the project, Chatwins is now able to offer a wider range of products using a considerably more efficient and effective print and apply labelling system.

In addition to operational flexibility, the project generated savings of more than £18,000 per annum and delivered an impressive ROI in just 12 months.