Zentia is the UK’s market leading manufacturer of complete ceiling solutions. Manufacturing a wide range of mineral ceiling tiles, suspension grids, and floating ceiling systems at two factories in Gateshead, Tyne and Wear, the company boasts over 100 years of knowledge and experience, having evolved from predecessor Armstrong Ceiling Solutions.

As the UK’s only major ceiling manufacturer, Zentia can offer a short supply chain to the construction industry in the UK and Ireland, providing specifiers and ceiling contractors with reliable products they can trust.

A key part of that capability stems from a highly industrial manufacturing facility which feature a high degree of automation.

With a 24/7 operation to keep up and running and capable of producing upwards of 50,000 square metres of ceiling tiles per day, the company was keen to automate processes throughout production, extending right through to labelling and packing at the end of the line.

In 2018, a print and apply solution was specified from an alternative supplier. However, the original system wasn’t fit for purpose and caused the company a lot of headaches, so Dylan Walker, Lead Process Improvement Engineer at Zentia looked for an alternative.

“We asked our suppliers and partners for recommendations and were introduced to Cobalt Systems. Their team came to look at our set up and in turn we went to see where the Cobalt machines are manufactured and that led to Cobalt recommending a continuous operation print and apply solution that fitted our industrial manufacturing environment.”

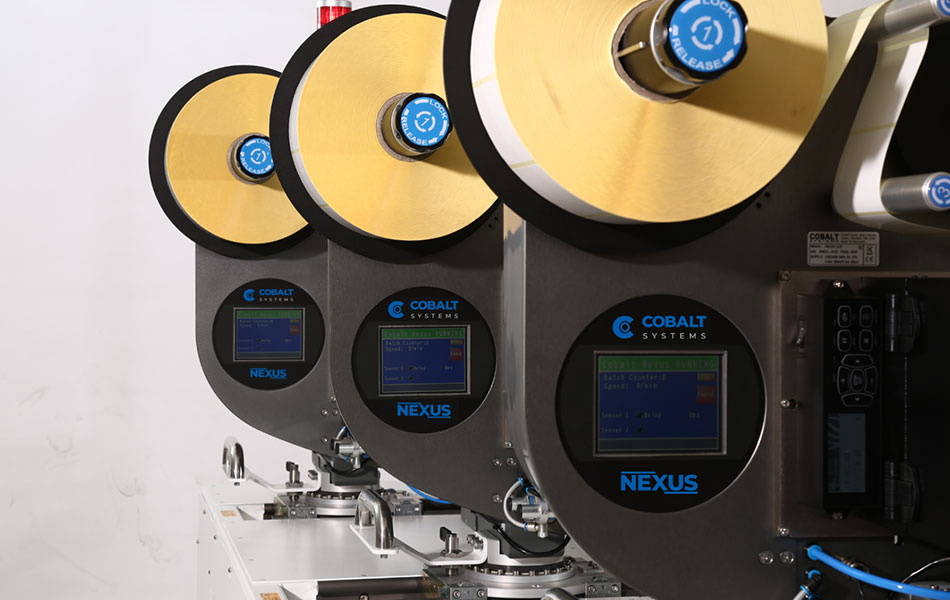

The solution comprises two Nexus 20 Linear machines configured to print and apply to the side of cardboard wrapped ceiling tiles, ahead of shrink wrapping and palletisation. The primary machine handles the bulk of the print and apply activity, with the second machine acting as a failsafe when label media needs to be replenished or planned maintenance is carried out.

The solution means the line never needs to stop; for Walker, that’s a big tick in the box.

“Part of my role is to look at what causes downtime on the line and where we can make improvements. Before the Cobalt solution, we just couldn’t rely on our setup and it was a major source of downtime. For us, that is a big problem as it takes time to restart the line, and that’s time that is lost forever.”

In addition to the print and apply function, fixed scanners provide real-time validation of print quality and automatically trigger reprints should a label error be identified.

The nature of the manufacturing process means the environment is dusty, so to overcome the issues of dust build up, the machines are housed in a positive pressure enclosure, which keeps the air circulating inside clean and dust free. This is another big plus for Walker.

“Knowing that the machines will just get on with printing and applying labels and we don’t need to be concerned with dust has saved us a lot of time and energy.

For Zentia, the comparison between the Cobalt machines and the previous system is like night and day.