The Cobalt Sentinel In-line Barcode Verifier

In-Line barcode verification checks the quality and scan-ability of a barcode by examining the visual aspects of the code in-line with industry standards and specifications. ISO/IEC 15416 requires 7 attributes to be tested in up to 10 separate positions of each barcode to devise an alphabetic grading from A to D, or fail.

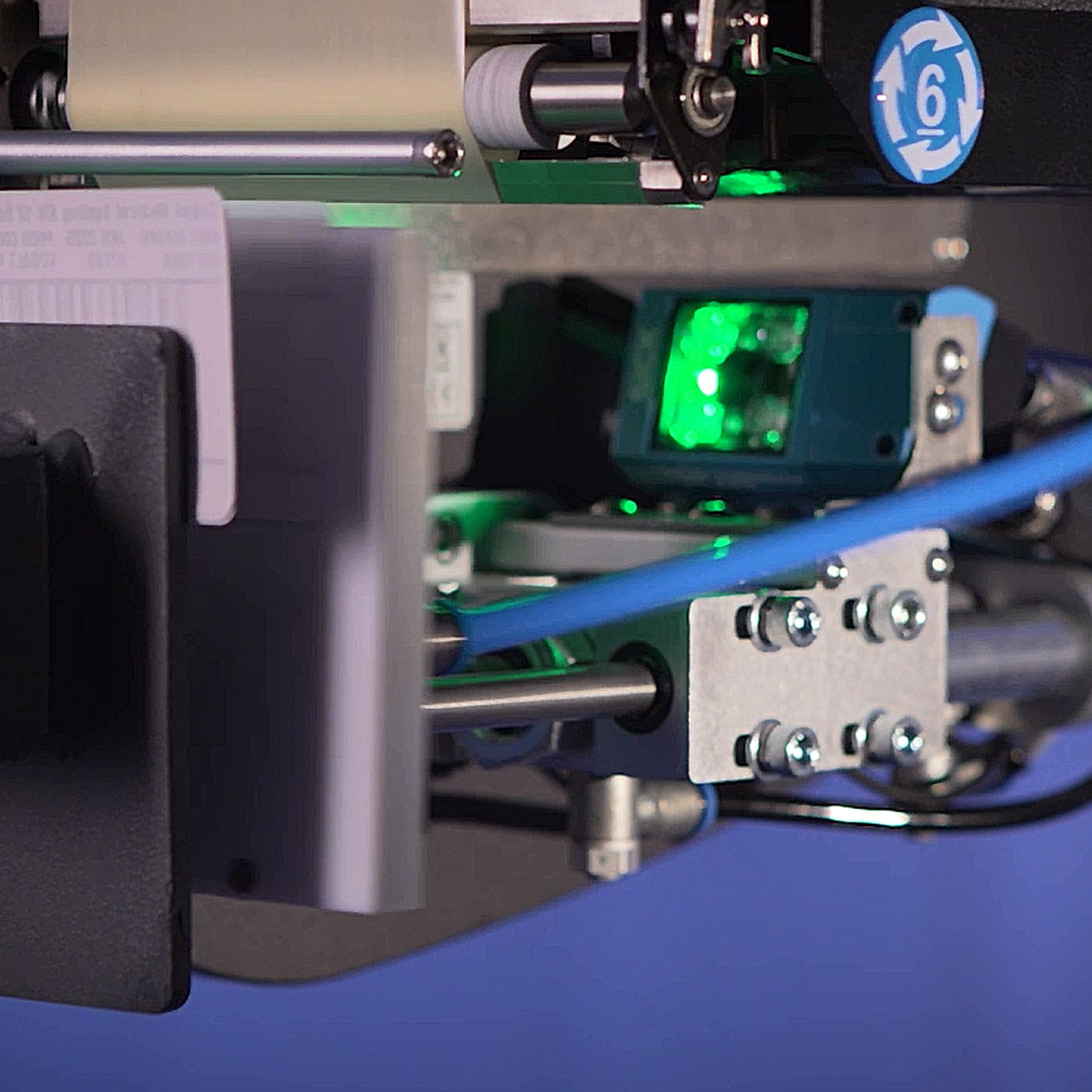

Cobalt Sentinel is our award-winning in-line barcode verification system that verifies barcode quality at the point of printing and validates data on cases, packs or pallets post-application.

The Cobalt Sentinel is now an integral part of all Nexus 20 Print and Apply systems, having been condensed to create the Sentinel Onboard.