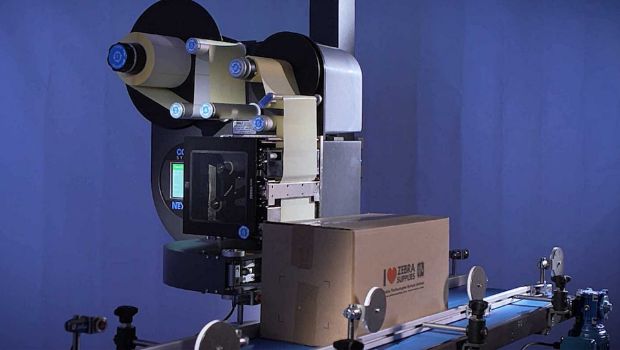

Case Labelling

Adaptable and intelligent, our Case Labelling systems (TUC) cater for print and apply barcode labelling of cases via side, top, front, bottom and two adjacent sides.

The modularity designed in our systems ensures both natural adaptation and upgrade opportunities, guaranteeing a Case Labelling solution that meets the needs of your packing line today and in the future.

Designed in consultation with production management from leading manufacturers, our systems have been developed to maximise uptime/OEE with the lowest cost of ownership.