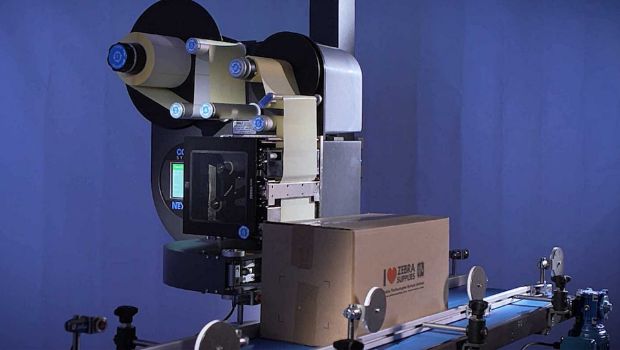

Continuous Operation Labelling

No more downtime from label replenishment or system maintenance

In high-speed packaging lines, Overall Equipment Effectiveness (OEE) is everything. As the market-leading specialist in print and apply systems, we understand that downtime equals disruption and loss of revenue.

With our continuous operation systems, there is no need to stop for label replenishment or preventative maintenance, so your lines keep running. Our systems also deliver an excellent return on investment for lines running at 40 packs a minute and above.

Our continuous operation systems operate at 99% performance efficiency. Each part is designed, manufactured, and selected to achieve a 24-hour, 7-day working week running at speed. Each critical component is optimised to support extended trouble-free operation.

As with all inline print and apply systems in the NEXUS 20 range, our continuous operation systems feature quick and reliable automatic onboard verification through the Cobalt Sentinel inline verifier.