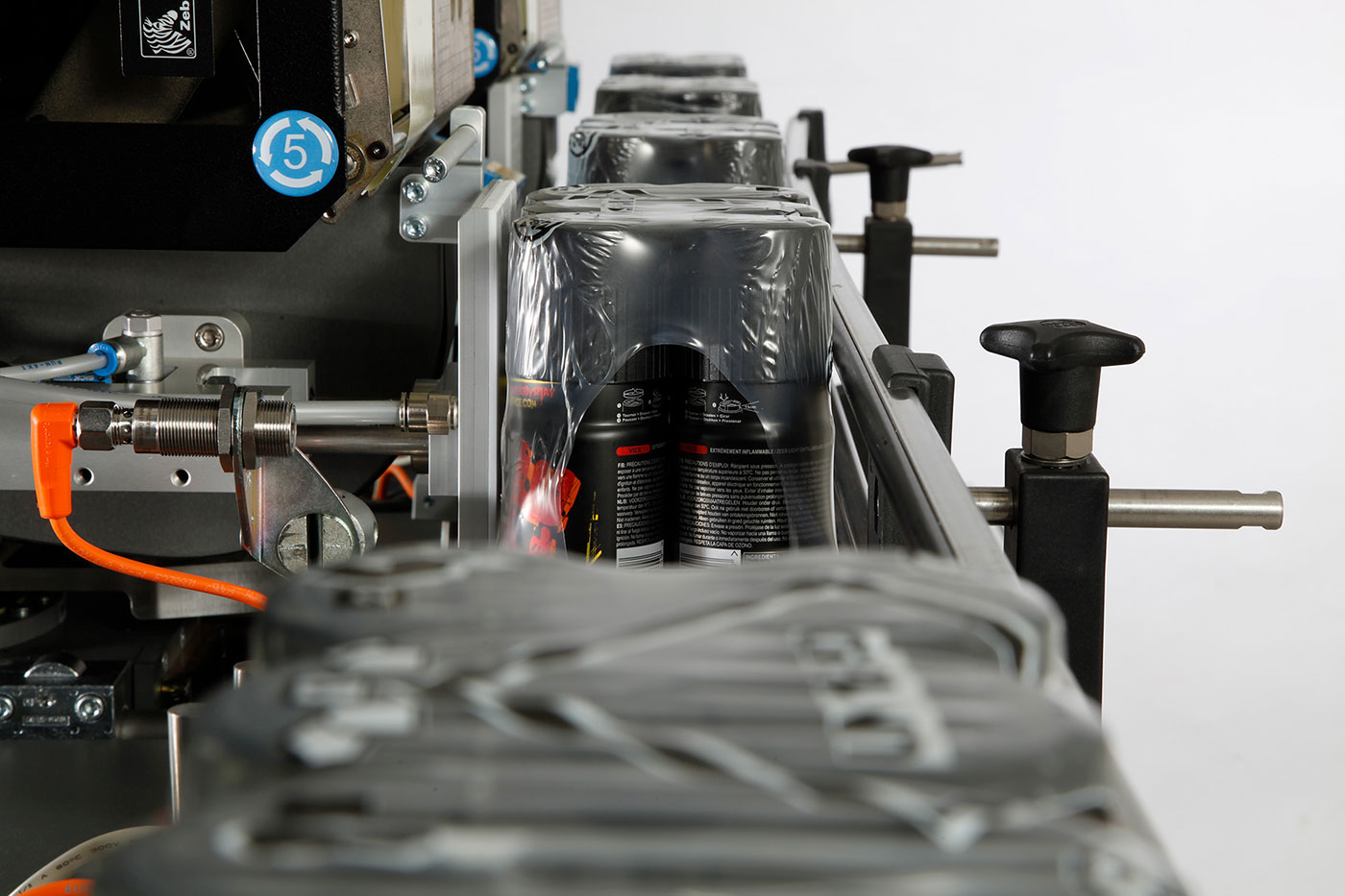

Pack Labelling

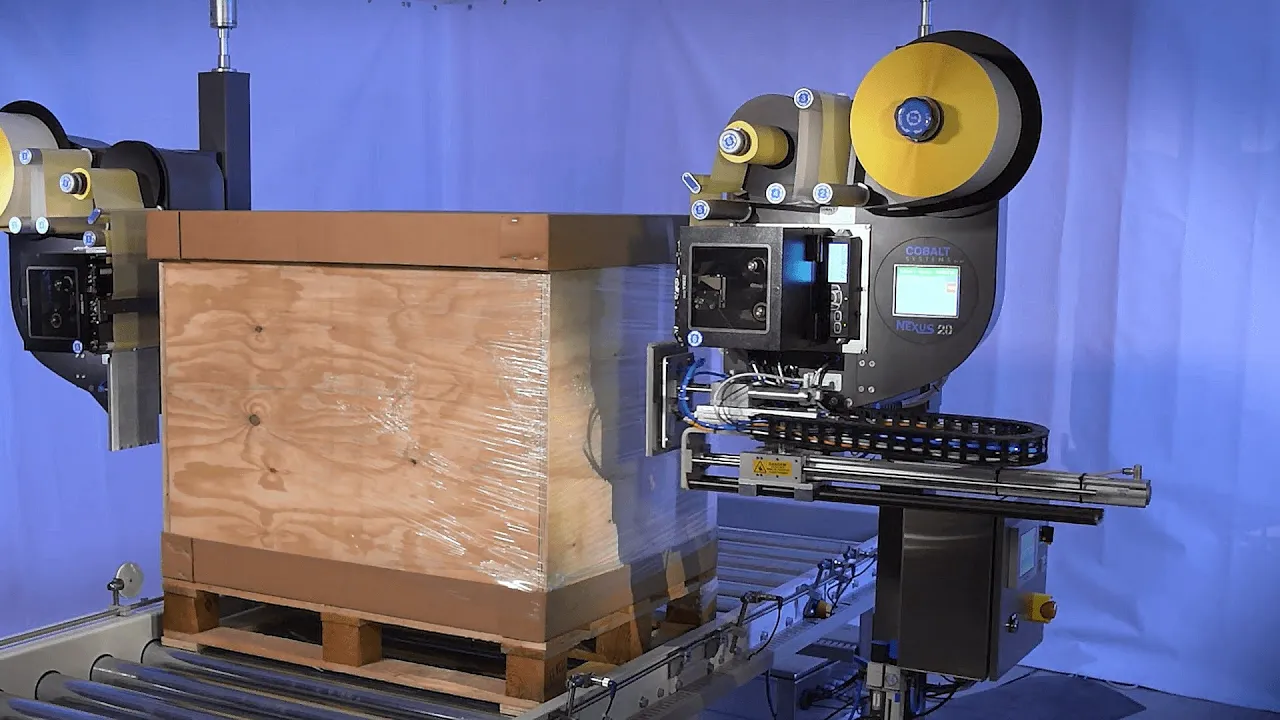

Whatever your pack labelling challenges, our market-leading, high-speed shrink-wrapped pack (TUC) labelling technology and expert management support can be relied upon to generate a rapid return on investment for your organisation.

Delivering speeds of 80 packs per minute with incredible accuracy, our real-time Print and Apply pack labelling systems do not need speed synchronisation or special conveyor systems to operate, driving down your cost of ownership.